Alles over hijsbanden

In the industry, construction, production and transport, slings are crucial for lifting heavy and bulky loads. Slings are easy to adjust and offer flexibility, making it possible to lift bulky or heavy loads safely and effectively. In order to guarantee safety during the lifting operation precautions for safe use.

Types of lifting slings

Lifting slings come in different designs, each with specific benefits and features. Below are some popular types of lifting slings:

The belt type sling:

The most commonly used type is the belt type sling that has a reinforced eye on each side. These are generally made of polyester, nylon or polypropylene. They are excellent for all kinds of lifting jobs, as they are adaptable, lightweight and easy to handle. They come in a large number of different lengths and load capacities.

The endless flat sling:

The belt type sling is also available in an endless version. This is often wrapped around the load. This is also available in many different lengths and load capacities.

Round slings:

These slings have excellent strength and flexibility because they are formed from a continuous loop of polyester or nylon fiber. Round slings are perfect for delicate loads and uneven shapes because they are soft on the loading surface and provide a firm hold. They also come in different lengths and capacities to meet different lifting needs.

Steel rope slings:

These slings are incredibly strong and resistant to heat, wear and corrosion, as they are composed of steel cable. Steel rope slings are generally used in heavy duty lifting applications that require high strength, flexibility and resistance to environmental conditions. To meet different lifting requirements, they are available in a variety of configurations, including single-piece, multi-piece and braided.

Chain slings:

These slings are made of steel chains and are the most durable and strong lifting slings. They are ideal for heavy loads and harsh lifting environments that require high strength and resistance to wear. Chain slings are available in different grades of steel, such as class 80, class 100, class 120 or stainless steel to meet different payloads and environmental requirements.

Different Kinds of Lifting Slings

But which lifting belt do you need for which job?

That depends a lot on the traits you're looking for; such as the environment, the load, the lifting frequency or even the requirements of certification bodies. It always starts with determining the required workload.

Workload:

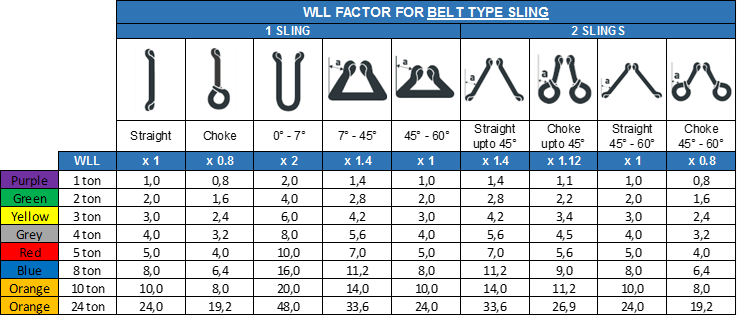

The working load limit (WLL) of a lifting sling is the maximum weight at which the lifting sling is designed. It is the amount of weight that the lifting sling can lift without exceeding the design capacity and compromising the safety of the lifting operation. The WLL should always be indicated on the lifting sling. In addition, the color of the lifting sling also shows what the WLL of that lifting sling is.

It is important that the WLL of a lifting sling should never be exceeded, this can lead to accidents resulting in serious injury and damage. The WLL of a lifting sling should always be considered in combination with other factors, such as the angle of the load, the condition of the lifting equipment and the experience and training of the operator. A good example; Do you use the band poached? Then reduce the workload to a WLL by a factor of 0.8.

To ensure safe lifting operations, it is critical to carefully select the right lifting sling for the job, regularly inspect lifting equipment, maintain it properly, and provide adequate training and supervision to personnel involved in the lifting operations.

Safety factor:

The safety factor (SF) is the ratio between the working load limit (WLL) and the breaking strength of the lifting sling. TETRA lifting slings have a safety factor of 7:1, which means that the lifting sling remains intact even if it is loaded at 7 times the WLL. The safety factor varies depending on the type of lifting sling and the application (see below). For example, the safety factor for wire rope slings is usually 4:1, while the safety factor for chain slings is usually 5:1. The workload limit must never be exceeded!

Example: different WLL limits corresponding to color indications

Bedenk dus goed wat de hijstaak is en welke omstandigheden hier invloed op hebben. En volg goed de gebruiksaanwijzingen van de fabrikant op!

The application of lifting slings

Lifting slings are used in various applications to lift and transport large objects safely and effectively. But what are the most typical applications for lifting with lifting slings? Here are the most common ones in a row:

Construction:

To raise and move building materials such as steel beams, concrete blocks and pipelines, lifting slings are often used on construction sites.

Production:

Lifting slings are used in factories to lift and move heavy equipment, such as boilers, turbines and compressors. They are also used to lift and move raw materials, such as steel rollers, pipes and plates.

Transport:

Lifting slings are used in the transport sector to load and unload large items, such as cars, machines and containers. To prevent movement and damage, they are also used to secure cargo during transport.

Mining:

To lift and move large objects such as boulders, ores, and minerals, mining operations require lifting slings. Drills, loaders and conveyors are some examples of the heavy mining equipment that is lifted and moved with them.

A crane lifts a tube by means of a lifting sling

Advantages of polyester slings

Extremely versatile tools for hoisting! But what makes it so convenient compared to other types of lifting equipment? The following are some of the advantages of using polyester slings:

Versatility:

Lifting slings can be used to lift different weights, from small to large and from light to heavy. They can also be used to lift weights of whimsical sizes and shapes, which can be challenging without lifting slings.

Flexibility:

Lifting slings are adjustable and can be made to accommodate any load, regardless of size or shape. To meet different lifting requirements, they can be used in different lifting configurations, as described above.

Lightweight:

Polyester slings are perfect for lifting jobs in tight locations and challenging terrains, as they are portable and easy to operate. They're also transportable and lightweight, making it easy to carry them from one place.

Cost-effective:

Lifting slings can be used for many lifting tasks and are cheap, so not very expensive to replace. They also require less maintenance than chains.

Polyester slings unfortunately also have disadvantages

Polyester slings offer a number of advantages, but there are a few disadvantages that must be taken into account before use. The following are some disadvantages of using polyester slings:

Load limitations:

Lifting slings have load restrictions that must be met to avoid overloading and failure. To ensure safe lifting operations, it is crucial to choose the right type and use it within its weight capacity.

Wear:

Lifting slings are subject to wear and tear due to prolonged use, environmental variables and improper use. The slings must be inspected regularly (visually) and when damage or wear is visible they must be replaced.

Potential for slippage:

If lifting slings are not securely attached to the load or if the load moves, while it is being lifted, they can slide off the load. This can be partially prevented by lifting the load correctly and securing the load first.

Injury risk:

If lifting slings are used improperly or do not work properly during lifting, there is a risk of injury or damage. When using lifting slings, it is crucial to take the right safety measures and follow the right instructions.

Safety instructions for the use of lifting slings

When using lifting slings, it is crucial to take the right safety measures to be able to lift safely and effectively and to minimize the risk of injury or damage:

De juiste hijsband selecteren:

The weight, shape and size of the load should all be taken into account when choosing the right lifting sling. Check that the lifting sling is in good condition and that the load is not exceeded.

Inspect the lifting sling:

Before using the lifting sling, pay attention to wear and tear, such as indentations, abrasions and fraying. If defects are discovered, do not use the lifting sling.

Secure the load:

Make sure that the lifting sling is securely attached to the load and that the lifting strap is securely attached to the hook or crane. Never exceed the maximum load capacity of the lifting sling.

Communicate and coordinate:

Make sure that everyone knows what to do and that there is good communication between the lifting operator and other parties involved.

Follow the safety procedures:

Follow the safety regulations. To avoid injury and property damage, you must comply with all safety rules and regulations, including the use of personal protective equipment (PPE).

Inspection of Lifting Slings

The operation and safety of lifting slings can be affected by wear and environmental variables. Regular inspections by trained experts are required to ensure that lifting slings can be used safely and efficiently.

Before each use, the user performs a visual check to check for damage, such as cracks, deformation or contamination, and it must also be checked whether the label is correct. The lifting sling must be decommissioned until any damage or irregularities have been rectified or replaced.

From a legal point of view, it is not possible to find out in the Working Conditions Act (Article 7.4a) when, where or how often a lifting sling must be inspected. The EKH states that lifting slings must be inspected every year. Most lifting tools can be tested dynamically, but this is not possible with plastic lifting slings. This is because after testing there is no indication of service life or residual quality with plastic lifting slings. That is why the following points of attention (rejection criteria) are used during inspection to determine whether a lifting sling needs to be replaced.

Disapproval criteria:

There are different rejection criteria for lifting slings, which may differ depending on the application, the country and the industry in which the lifting slings are used:

- Tissue damage: Any kind of tearing, cutting, burning or sanding of the tissue can lead to a rejection

- Damage to the stitching: If the stitching is loose, damaged or weakened, the lifting sling is unusable.

- Age: Lifting slings have a maximum service life and must be replaced regularly. If a lifting sling is older than the recommended maximum service life, it should be rejected.

- Overload: If a lifting sling is overloaded, it can lead to damage to the fabric or stitching, making it unusable.

- Exposure to chemicals: If a lifting sling is exposed to harmful chemicals, it can affect the structure of the fabric and render the lifting sling unusable.

- Exposure to UV light: Due to UV light, lifting slings age faster, so it is important to store them in a place where they are not exposed to sunlight.

Maximum lifespan:

The service life of lifting slings depends on a number of things, such as the quality of the material, the type of use and the environment in which they are used. The maximum service life of lifting slings is determined by the manufacturer, this can vary from one year to decades.

Conclusion

In many different industries, lifting slings are crucial equipment for lifting large items quickly and safely. They have a number of advantages, including adaptability, flexibility, weight and affordability. They also have some drawbacks, including wear and tear and the potential for slippage. Before using lifting slings, it is crucial to examine them and, of course, to adhere to the correct safety measures. Polyester slings are, if used correctly, a safe and efficient lifting solution. If you are considering using lifting slings for lifting loads, it is crucial to understand their pros and cons and follow proper safety measures to avoid accidents and injuries.

Share article?

Ready for your next job?

Compare our lifting slings and ensure safety and reliability during lifting.